Lithium-Ion Battery Care Guide

The cycle life of lithium batteries is a critical indicator of their performance and durability. It can be explained from the following dimensions:

1. Definition Dimension

Charge and Discharge Cycles: Cycle life typically refers to the number of charge and discharge cycles a battery can undergo before its capacity declines to 80% of its initial capacity.

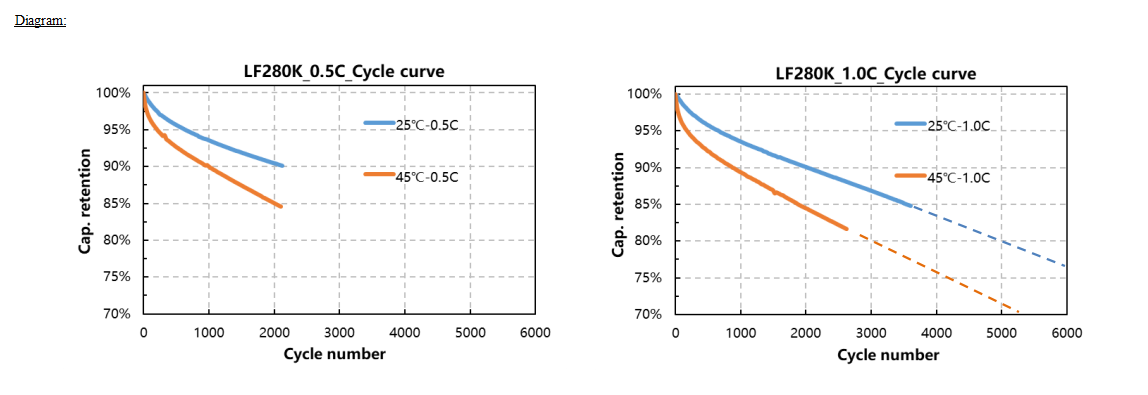

Standard Conditions: The definition of cycle life depends on specific test conditions, including charge and discharge rates, depth of discharge (DoD), and temperature. For example, cycle life under 0.5C charge/discharge at 25°C may differ significantly from that under 1C charge/discharge at 45°C.

2. Influencing Factors Dimension

Depth of Discharge (DoD): Higher discharge depths generally result in shorter cycle life. For instance, shallow cycles (30% DoD) can significantly extend cycle life.

Temperature: High temperatures accelerate side reactions within the battery, reducing cycle life, while low temperatures may lower cycling efficiency, also affecting longevity.

Charge and Discharge Rates: High-rate charging and discharging can increase internal resistance or material degradation, leading to shorter cycle life.

Stability of Electrolyte and Materials: The choice of materials (cathode, anode, electrolyte composition, etc.) is critical to cycle life.

3. Testing Dimension

Static Testing: Measuring battery cycles under constant conditions, such as standardized charge/discharge tests in laboratories.

Dynamic Testing: Simulating complex real-world conditions, such as variable load profiles during vehicle operation.

Industry Standards: Different industries have specific protocols for testing cycle life (e.g., IEC, UL, or Chinese national standards).

4. Application Scenarios Dimension

Consumer Electronics: For devices like smartphones and laptops, cycle life typically ranges from 300 to 500 cycles, as users can tolerate some capacity degradation.

Electric Vehicles: Batteries are expected to maintain high capacity even after 1,500–3,000 cycles to ensure long-term vehicle usage.

Energy Storage Systems: Due to frequent charging and discharging, energy storage batteries need to achieve more than 5,000 cycles.

5. Evaluation Metrics Dimension

Capacity Retention: The remaining capacity as a percentage of the initial capacity after a specified number of cycles.

Internal Resistance Changes: The rate at which internal resistance increases during cycling, directly impacting battery output performance.

Energy Efficiency: Whether the charge/discharge efficiency significantly decreases after multiple cycles.

Safety: Whether the battery becomes prone to swelling, thermal runaway, or other safety issues in later stages of its cycle life.

6. Technical Improvement Dimension

Material Enhancement: Using highly stable cathode materials (e.g., lithium iron phosphate) or adding modifiers.

Design Optimization: Improving manufacturing processes to reduce internal resistance and side reactions.

Thermal Management Systems: Effective thermal management to control temperature rise and extend cycle life.

By analyzing these dimensions, one can gain a comprehensive understanding of the cycle life of lithium batteries and select suitable battery solutions for different application scenarios.